The Experiment Acceptance Review - Part 1

- mrgboucher

- Jan 21, 2022

- 4 min read

The Experiment Acceptance Review or EAR was a key point of the experiment testing. It was a one-day crash test where every single piece of every single part of the experiment was tested. The REXUS/BEXUS team came here, to our HQ in Stockholm Sweden, to assess the experiment and give or not its approval for further continuation. It was therefore crucial that the team was in order, ready to show all the tremendous work we had been doing these past months. If any problem would have occurred, it was also a chance to fix it before the actual launch, and hence avoid a catastrophic and unwanted crash of our beloved Boom.

To let you feel and dwell on the experience of the EAR as if you were there, here are the terrific experiences of Mathias, Arjun, and Leon from this very special day.

Mathias- Head of Project

The worst part about any REXUS/BEXUS review is the short lapse of time before it happens when you are waiting. At that time you are aware of what will go right, and what will go wrong. There is no time to change anything. You can only wait for everyone else to arrive. After the initial nervousness has subsided, the review becomes more enjoyable. My favorite thing that happened during the EAR review was the weight check. Seeing the scale stay at 11000g, our experiment's weight constraint is something I will remember for a long time. Mostly because I never want to experience it again.

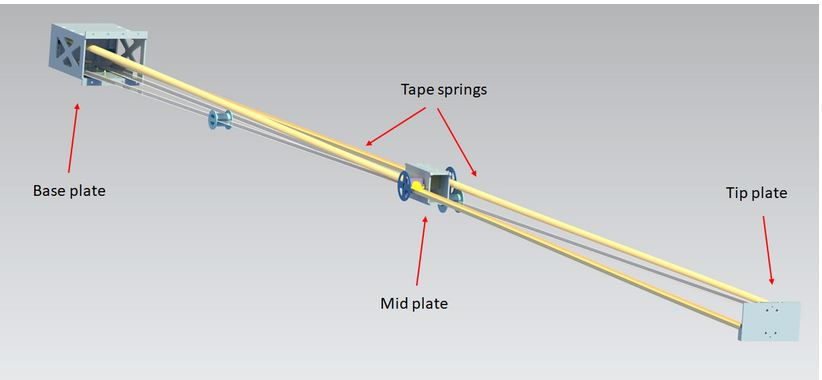

LEON- Tape Springs specialist and manufacturer

We have been working intensely and without rest on the boom deployment mechanism up to the EAR. New tape springs were loaded in the boom and we were quite excited to talk to the REXUS team about our updated loading mechanism and how the manufacturing of tape springs will progress.

The presentation went smoothly but the big challenge was the live demonstration of the boom deployment system. To do so, the gravity off-loading set-up was prepared and everybody present gathered around it. After the battery is plugged in, the boom has a countdown of 34 seconds before deployment.

During this time, it is a mixture of emotions of excitement and absolute focus to see what happens. 3,2,1 click, the HDRM line is cut by the pyro cutter and the leaf springs are pushing the tip plate out. However, to the shock of everybody, the retention line got stuck and the boom didn’t open at first. The plastic piece which jammed the mechanism was visible from the side. A simple touch was enough to make the boom deploy as planned.

The REXUS team had a few points to discuss the boom and made clear that they would like a more quantitative measurement of the tape spring forces. The boom deployment was discussed, and it was pointed out that during free fall this jamming wouldn’t occur as a little vibration would already make sure that the boom deploys.

Overall, the feedback was positive and encouraging. We will keep testing and polishing the deployment to assure that our mechanism is repeatable and robust.

Arjun- Ejection Mechanism specialist

The EAR started early in the morning at 08h00. In the days before that, I made sure the most recent (and longest-lasting) problem with the rail spacing was solved, and now the flight FFU snugly fit within the ejection mechanism cavity while experiencing minimal friction.

A single manual (i.e. without using pyrocutters) hatch ejection test was performed and the system performed as it should have. The EAR was the first time the FFU ejection was to be tested for the flight unit. The test unit was fully tested, but there are always inherent uncertainties with new parts.

After the initial greetings and coffee, we started with a rundown of the day. Many aspects of the experiment were discussed at length. The first demonstration was the ejections. I started with pulling out the launch and ejection tensioning checklists and handed a copy each to Armelle from SSC and Giorgio from ESA. Then I started the tensioning procedure.

While I was experienced in tensioning it fully within a set period of time, everything is different when doing it for an official EAR, and it took a little bit more time than expected. Thankfully Marci helped a lot and motivated me. The first tensioning was not successful and so we detensioned and tried again. The second attempt was successful but by now we had realized that one must overestimate the time required for experiment preparation - something to be noted for future events like Integration week and the launch campaign.

Then Andreas with Mathias’s help connected and prepped the ground station. We prepared the “landing area” for the hatch and FFU - basically used a lot of foam in the ejection area. After taking our positions and pointing the cameras, Andreas gave the command to eject the hatch. It was as intended.

I checked the pyrocutter holders, and they had no signs of damage. Then the FFU ejection signal was given through the ground station. The FFU also happened successfully. There was a crack on the back (FFU) pyrocutter along the grain of the 3D print, which is where one would expect a crack if at all. This was replaced later on.

All in all, the EAR was a unique experience where one could see for the first time the entire experiment coming together. Having experienced professionals guide our thought process was also helpful. While most of the time the people work on their subsystem, this was, at least for me, the first time that I saw what kind of problems my teammates were trying to solve.

Comments