Shaking our experiment to pieces

- mrgboucher

- Nov 10, 2021

- 2 min read

Last month has been incredibly busy for the team. We just had our Experiment Acceptance Review. It went well. This was the last review for the experiment before the launch and we are now waiting for the results. We will talk a bit more about it in a next blog post. After that comes integration testing with the other experiment that will fly on our rocket.

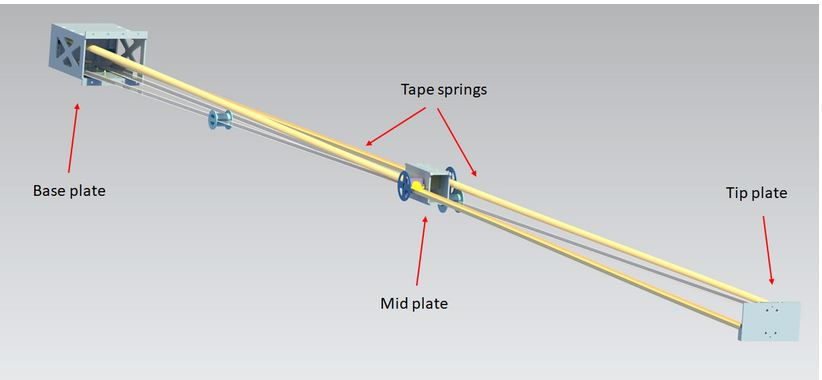

As part of the preparation for the Experiment Acceptance Review we recently performed vibration testing on the Magnetometer Boom Assembly, our experiment payload. Below you can see the Magnetometer Boom attached to the vibration table.

During the vibration testing we run a sample, in this case the Magnetometer Boom Assembly, through a series of vibration profiles provided by the REXUS/BEXUS team. We start by running a low level sinusoidal sweep. During the sweep we vibrate the sample at increasing frequencies and record how different parts of the boom behave. Then the sample is exposed to more intensive vibrations that approximate the vibration environment during the launch of the REXUS rocket. We then finish with another low level sinusoidal sweep. We can then compare the sweeps done before and after the intensive vibrations. If there are large differences it indicates that something in the sample may have broken. In addition to this we also performed functional tests of the Magnetometer Boom Assembly before or after the vibration testing. Finally we inspect the boom for any damage.

In the end the experiment wasn’t shaken to pieces. As for our results, the first iteration of the test caused the boom to jam during deployment. After fixing the issues that caused this, we of course had to rerun the vibration test to verify that our changes prevented the jamming. It was quite a relief when the boom deployed after the second vibration test.

However the deployment was not perfect. Small cracks in the tape springs caused unwanted bending which prevented the boom from successfully deploying. To prevent this it was decided to use fresh tapesprings for the final experiment assembly.

Don't forget to check our social media for more updates!

Mathias

Comments